Application

Solutions That Shape Every Industry We Touch

PVC Pipes & Fittings

Empowering Sustainable Infrastructure with Tin based & Performance Additives

S V Plastochem provides advanced stabiliser systems and processing additives for rigid PVC pipes and fittings. Our solutions are engineered to ensure long-term thermal stability, high mechanical strength, and smooth processing for pressure and non-pressure pipe applications.

Key Challenges in the Segment

Thermal degradation during high-temperature extrusion

Poor long-term heat stability and discoloration

Inconsistent fusion and melt flow

Surface defects and die build-up

Compliance with potable water and infrastructure standards

Low Viacat Softenng Point and failur in Stress Relieving Test as per ISO Standard

Recommended Product Range

| Product Type | Key Products | Function / Use Case | |

|---|---|---|---|

| Stabiliser | SV Stabiliser 10 | Improves heat stability and processing | |

| Lubricant | Wax Blend | Reduces friction, improves surface finish | |

| Modifier | Impact Modifier | Enhances toughness and flexibility |

Sustainability First

SVP is committed to helping PVC manufacturers transition to eco-safe additives without compromise. Our solutions are compliant with RoHS, and enable green certifications for end-use applications.

Client Testimonial

while complying with RoHS. We saw fewer rejections and better insulation values.

while complying with RoHS. We saw fewer rejections and better insulation values.

while complying with RoHS. We saw fewer rejections and better insulation values.

Lead-Free. Long-Lasting. Globally Compliant.

Partner with SVP to power your PVC pipe production with safe, sustainable, and high-performance additives.

PVC Packaging

Precision Tin-Based Additives for Better Stability, Adhesion & Flow

S V Plastochem offers high-performance stabiliser and lubricants designed for soft PVC film and calendaring applications where clarity, flexibility, and thermal stability are critical.

Key Challenges in the Segment

Maintaining high transparency and gloss

Thermal degradation during calendaring

Plate-out and roller contamination

Inconsistent film thickness

Flexibility loss over time

Recommended Product Range

| Product Type | Key Products | Function / Use Case | |

|---|---|---|---|

| Tin Mercaptides | Methyl Tin Stabiliser, Butyl Tin Stabiliser | Superior clarity, thermal stability and transparency | |

| Tin Maleate | Di Butyl Tin Maleate | Odourless applications | |

| Metallic Stearate | Calcium Stearate, Zinc Stearate, Barium Stearate | Acts as internal lubricant & co-stabiliser for PVC processing | |

| Calcium – Zinc Stabilisers | Ca-Zn Stabiliser Grades | Non-toxic stabilizers for packaging applications | |

| Lubricants & Additives | N-Butyl Stearate, SV Pack Lub G, SV Pack Lub 116, OPE Wax, Epoxidised Soyabean Oil, Stearic Acid, Processing Aid & Impact Modifier | Controls lubrication balance and surface quality along with mechanical properties |

Safety +Sustainability

SVP’s solutions help you manufacture eco-compliant, durable, and safe cable compounds. Our additives meet stringent global benchmarks including UL-94, RoHS, and non-lead standards, supporting your move to green-certified products.

Client Testimonial

Formulate Coatings & Adhesives with Performance & Precision.

With global-grade additives and technical support, SVP partners with manufacturers across the paint, sealant, and adhesive value chain.

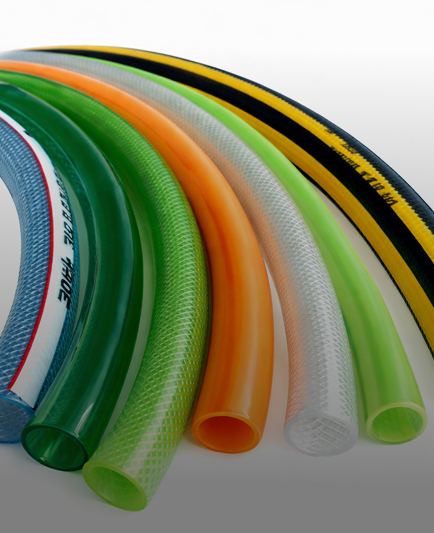

PVC Tubing

Precision Tin-Based Additives for Better Stability, Adhesion & Flow

S V Plastochem provides stabiliser and additive systems tailored for flexible PVC tubing applications requiring durability, flexibility, and resistance to environmental stress.

Key Challenges in the Segment

Heat degradation during continuous extrusion

Loss of flexibility and elasticity

Poor abrasion and aging resistance

Inconsistent wall thickness

Migration of additives

Recommended Product Range

| Product Type | Key Products | Function / Use Case | |

|---|---|---|---|

| Tin Mercaptides | Methyl Tin Stabiliser, Butyl Tin Stabiliser, Antimony Stabiliser | Maintains thermal stability, transparency and flexibility | |

| Calcium – Zinc Stabilisers | Ca-Zn Stabiliser Grades | Environment-friendly stabilization | |

| Lubricants & Additives | N-Butyl Stearate, Epoxidised Soyabean Oil, Stearic Acid | Improves processing and melt flow, enhances surface properties |

Safety + Sustainability

SVP’s solutions help you manufacture eco-compliant, durable, and safe cable compounds. Our additives meet stringent global benchmarks including UL-94, RoHS, and non-lead standards, supporting your move to green-certified products.

Client Testimonial

Formulate Coatings & Adhesives with Performance & Precision.

With global-grade additives and technical support, SVP partners with manufacturers across the paint, sealant, and adhesive value chain.

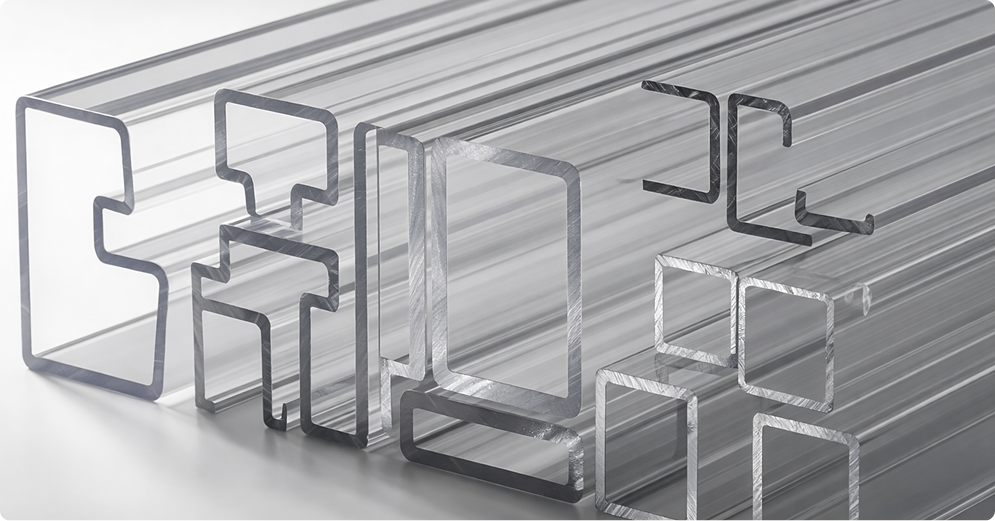

PVC Profiles & Foam Boards

Weather-Resistant, UV-Stable Additives for High-Durability uPVC Profiles

S V Plastochem solutions support rigid PVC profile and foam board manufacturers with products that deliver excellent fusion, dimensional stability, and superior surface quality.

Key Challenges in the Segment

Fusion control during extrusion

Surface roughness and discoloration

Dimensional instability

Heat resistance during long production runs

Weathering performance

Recommended Product Range

| Product Type | Key Products | Function / Use Case | |

|---|---|---|---|

| Tin Mercaptides | Methyl Tin Stabiliser, Butyl Tin Stabiliser | High heat stability and clean processing | |

| Calcium – Zinc Stabilisers | Ca-Zn Stabiliser Grades | Sustainable stabilization with good weather resistance | |

| Lubricants & Additives | OPE Wax, Calcium Stearate, Zinc Stearate, Epoxidised Soyabean Oil, Impact Modifier and Processing Aids | Improves processing, melt flow and mechanical properties | |

| Metallic Stearate | Calcium Stearate, Barium Stearate, Zinc Stearate | Lubrication and acts as a co-stabiliser |

Performance You

Can Count On

Our tin-based as well as calcium zinc systems are trusted by window profile manufacturers across Asia, Africa, and Eastern Europe, helping them meet ISO, REACH, and country-specific standards for performance and sustainability.

Client Testimonial

Precision Additives for Modern uPVC Profiles

Partner with SVP to build climate-resistant, regulation-compliant profiles for residential, commercial, and industrial use.

Wire & Cable

Reliable Stabiliser & Additives for Flame-Retardant, Flexible, and RoHS-Compliant Cable Insulation

S V Plastochem provides stabiliser and additive solutions for PVC and XLPE cable compounds ensuring electrical safety and long-term performance.

Key Challenges in the Segment

Thermal aging and insulation failure

Electrical property degradation

Poor process stability

Flame resistance requirements

Recommended Product Range

| Product Type | Key Products | Function / Use Case | |

|---|---|---|---|

| Tin Catalysts | Di Butyl Tin Dilaurate (DBTDL) | Catalyst for XLPE cable compounds | |

| Calcium – Zinc Stabilisers | Ca-Zn Stabiliser Grades | Heat stability and electrical safety | |

| Tin Mercaptides | Methyl Tin Stabiliser, Antimony Stabiliser | For transparent applications and sheathing | |

| Metallic Stearate | Calcium Stearate, Zinc Stearate, Barium Stearate | Lubrication and processing aid | |

| Lubricants & Additives | OPE Wax, Antimony Trioxide, Stearic Acid | For fusion control and FR applications |

Safety + Sustainability

SVP’s solutions help you manufacture eco-compliant, durable, and safe cable compounds. Our additives meet stringent global benchmarks including UL-94, RoHS, and non-lead standards, supporting your move to green-certified products.

Client Testimonial

Future-Ready Cables Need Future-Ready Additives

From electrical to automotive wire insulation, SVP provides tailored additive systems to meet global compliance and durability expectations.

Pharmaceutical Industry

Precision Tin-Based Additives for Better Stability, Adhesion & Flow

The Pharmaceutical Industry requires materials that meet high purity standards, strict regulatory compliance, and consistent batch quality to ensure safe and effective drug manufacturing.

Key Challenges in the Segment

High purity requirements

Regulatory compliance

Consistent batch quality

Recommended Product Range

| Product Type | Key Products | Function / Use Case | |

|---|---|---|---|

| Tin Compounds | Tin Metal, Stannous Chloride (Dihydrate), Stannic Chloride (Anhydrous & Pentahydrate), Tri n-Butyl Tin Oxide (TBTO), Tri n-Butyl Tin Chloride (TBTCL), Mono n-Butyl Tin Chloride (MBTCL), Sodium Stannate, Stannous Oxide, Stannic Oxide | Used in the pharmaceutical industry as catalysts, reducing agents, and intermediates in drug synthesis. | |

| Tin Catalysts | Di Butyl Tin Oxide (DBTO) | Catalyst to promote esterification, transesterification, and condensation reactions during drug synthesis. |

Safety + Sustainability

SVP’s solutions help you manufacture eco-compliant, durable, and safe cable compounds. Our additives meet stringent global benchmarks including UL-94, RoHS, and non-lead standards, supporting your move to green-certified products.

Client Testimonial

Formulate Coatings & Adhesives

with Performance & Precision.

With global-grade additives and technical support, SVP partners with manufacturers across the paint, sealant, and adhesive value chain.

Polyurethane (PU) Foam

High-Efficiency Tin Catalysts for Flexible & Rigid PU Systems

The Polyurethane (PU) Industry demands precise control over chemical reactions to achieve consistent foam quality, optimized cure speed, and reliable end-product performance.

Key Challenges in the Segment

Reaction control

Foam consistency

Cure speed optimization

Recommended Product Range

| Product Type | Key Products | Function / Use Case | |

|---|---|---|---|

| Tin Compounds | Tin Metal, Stannous Chloride (Dihydrate), Stannic Chloride (Anhydrous & Pentahydrate), Tri n-Butyl Tin Oxide (TBTO), Tri n-Butyl Tin Chloride (TBTCL), Mono n-Butyl Tin Chloride (MBTCL), Sodium Stannate, Stannous Oxide, Stannic Oxide | Used in the pharmaceutical industry as catalysts, reducing agents, and intermediates in drug synthesis. | |

| Tin Catalysts | Di Butyl Tin Oxide (DBTO) | Catalyst to promote esterification, transesterification, and condensation reactions during drug synthesis. |

Safety + Sustainability

SVP’s solutions help you manufacture eco-compliant, durable, and safe cable compounds. Our additives meet stringent global benchmarks including UL-94, RoHS, and non-lead standards, supporting your move to green-certified products.

Client Testimonial

FuturAchieve PU Foam

Consistency at Scale

Whether you’re producing flexible or rigid foams, SVP offers tin catalysts that deliver repeatable, reliable results across production runs.

Coatings, Paints,Resins & Adhesives

Precision Tin-Based Additives for Better Stability, Adhesion & Flow

The Paints, Coatings, Resins & Adhesives segment demands high-performance chemical additives that ensure precise curing control, strong adhesion, and long-lasting film durability. These parameters are critical for achieving consistent surface finish, mechanical strength, chemical resistance, and overall product reliability across industrial and decorative applications.

Key Challenges in the Segment

Controlled curing

Adhesion performance

Film durability

Recommended Product Range

| Product Type | Key Products | Function / Use Case | |

|---|---|---|---|

| Tin Catalysts | Di Butyl Tin Dilaurate (DBTDL), Di Butyl Tin Oxide (DBTO), Mono Butyl Tin Oxide (MBTO), Di Butyl Tin Diacetate (DBTA), Stannous Oxalate, SV Cat 102, SV Cat 101 | Accelerates curing, enhances film formation, and improves coating performance |

Safety + Sustainability

SVP’s solutions help you manufacture eco-compliant, durable, and safe cable compounds. Our additives meet stringent global benchmarks including UL-94, RoHS, and non-lead standards, supporting your move to green-certified products.

Client Testimonial

Formulate Coatings & Adhesives

with Performance & Precision.

With global-grade additives and technical support, SVP partners with manufacturers across the paint, sealant, and adhesive value chain.